Meaisín píopa HDPE

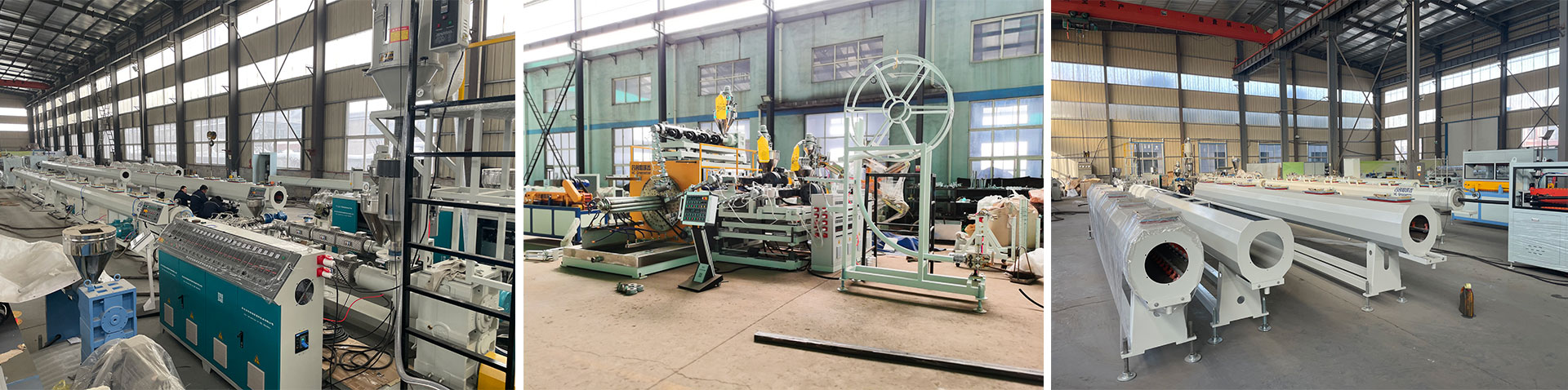

QINGDAO COMRISE MACHINERY CO., LTD.

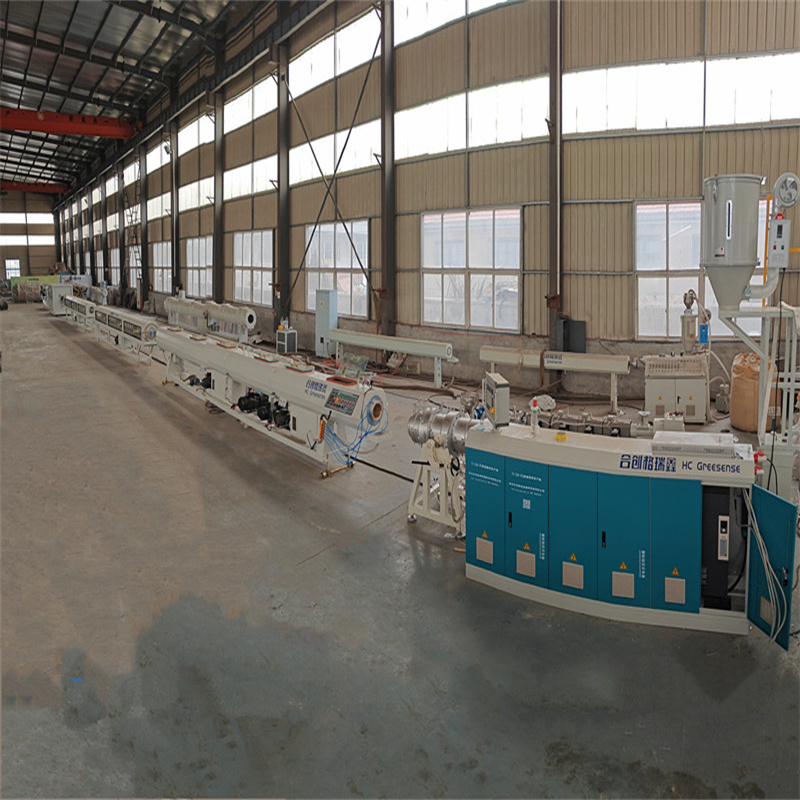

Our main product is HDPE Pipe Machine

The main products are popular in the domestic market, such as the East China market, Southwest market, Northeast market, Central China market, etc. The products are also exported to international markets, including Russia, Australia, Southeast Asia, the Middle East, and Eastern Europe. Africa and other country.

Pe pipe

Good hygiene performance: During the processing of PE pipes, no heavy metal salt stabilizers are added, the material is non-toxic, there is no scaling layer, and there is no bacterial growth, which solves the hidden danger of secondary pollution of urban drinking water.

Excellent corrosion resistance: except for a few strong oxidants, it can withstand corrosion from various chemical media; No electrochemical corrosion.

Long service life: PE pipes can be safely used for more than 50 years at rated temperature and pressure.

Better impact resistance: PE pipes have good toughness, high impact resistance, and can withstand heavy objects directly passing through the pipeline will not cause the pipeline to rupture.

Similer Product

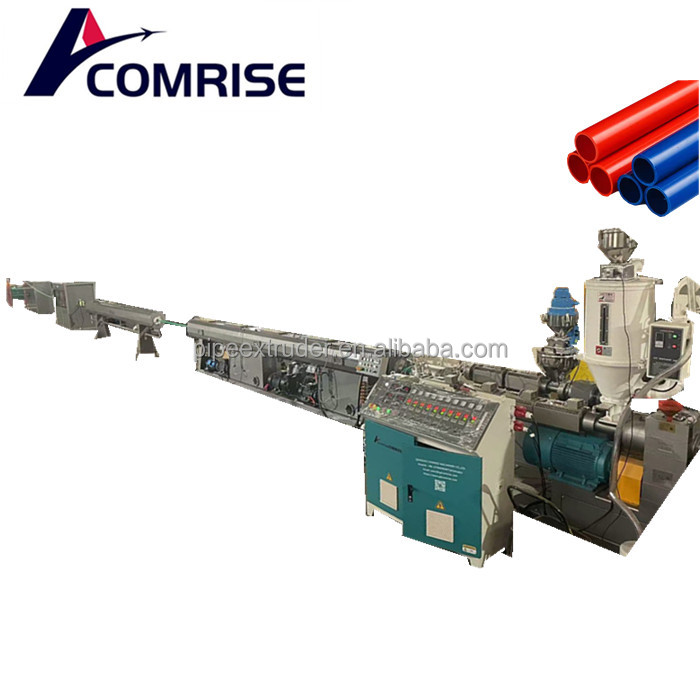

The PE (Polyethylene) pipe machine is a specialized piece of equipment designed for the production of polyethylene pipes. These pipes are widely used in various applications, including water supply, gas distribution, irrigation, and drainage systems. The PE pipe machine consists of several key components that work together to ensure efficient and high-quality pipe production.

ApplicationsWater Supply Systems: Municipal water distribution networks, residential and commercial water supply lines.

Gas Distribution: Natural gas pipelines, propane distribution systems.

Irrigation Systems: Agricultural irrigation, landscaping, and golf course watering systems.

Drainage Systems: Stormwater management, sewage systems, and industrial drainage.

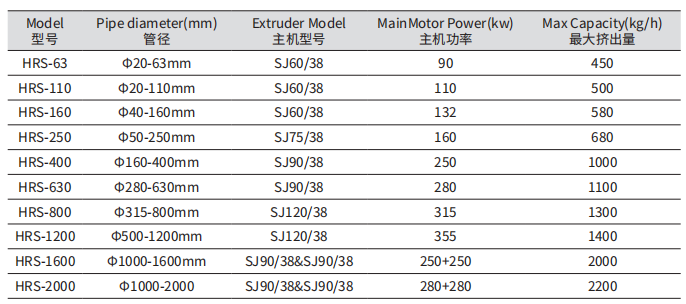

Specifiation Parameters

(1)ExtruderFunction:

The extruder is responsible for melting and extruding the polyethylene pellets into a continuous tube.

Features: High torque drive system, precision temperature control, and efficient screw design for optimal material

processing.

Longth ratio L / D :33:1

Material quality: 38CrMoAlA

Siemens motor

ABB inverter

Siemens PLC computer control panel

(2)New technology die head

The extrusion die adopts spriral structure to ensure uniform melt temperature, completely eliminate weld lines, overcome the stripe defect caused by blue die, and produce pipe products with smooth inner and outer walls and good compactness.

Pressure grades: as to customer table

(3)Vacuum sizing water tankFunction:

The cooling system rapidly cools the extruded pipe to maintain its shape and structural integrity.

Features: Multi-stage cooling tanks with adjustable water flow rates and temperature control to ensure consistent cooling.

vacuum pump:3 + 4 KW, 2 sets

Water pump: 3 + 4 KW, 2 sets

Tank material: 100% Stainless steel

Length: 6000 mm

(4)Spray water tank

Water pump : 4 KW * 1 set

Water tank material:stainless steel

Length : 6000mm

Over all size :6500×500×1300mm

(5)Halling off machine:

The traction device is designed to be able to pull the pipe in a continuous and stable state. Its compact structure, maintenance-free structure and absolute balance of operation are its outstanding features.

Clamping way:claw pneumatic

Traction speed:1-15m/min

Pulling motor:motor 1.5KW x 2

Mode of speed regulation:Frequency Control

(6)Cutting machine:

Cutting method:Rotary cutting with circular blade

Clamping way:Pneumatic clamp

Worktable movement way: Synchronous follow up, pneumatic reset

Revolution motor power:1.5KW

Method of electric control : Independent setting of high-speed counter and PLC linkage

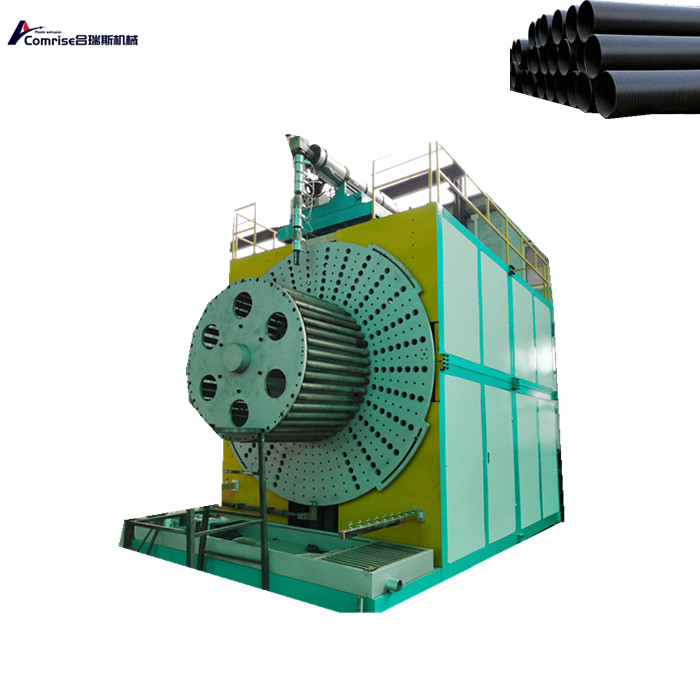

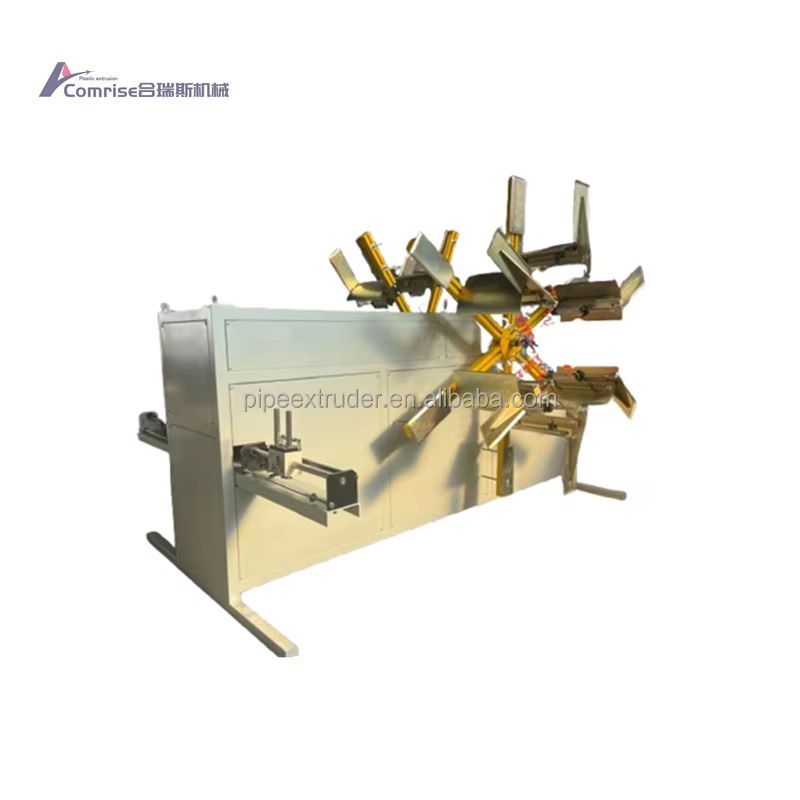

(7)Double station winding machine

The winding machine is used for small-sized 20-63mm PP PE PPR HDPE LDPE pipes. High winding efficiency

(8)Auto stocker

Stacker used for big size pipe.

About Us

High Production Efficiency:

Advanced extrusion technology ensures high output and consistent quality.

Automated control systems for precise operation and reduced labor costs.

Versatile Material Handling:

Capable of processing a wide range of polyethylene grades, including HDPE, MDPE, and LDPE.

Flexible production settings to accommodate different pipe diameters and wall thicknesses.

User-Friendly Interface:

Intuitive control panel with touch screen display for easy operation and monitoring.

Real-time data tracking and production statistics for better process control.

Robust Construction:

Heavy-duty frame and components for durability and long service life.

Low maintenance requirements and easy access for routine servicing.

Environmental Compliance:

Energy-efficient design to reduce power consumption and operating costs.

Minimal waste generation and recycling options for sustainable production.

GET A QUOTATION NOW

- View as

Meaisín píopa

Is déantúsóir ceannródaíoch Síneach é Comrise Innealra a dhíríonn ar threalamh easbhrúite píopaí plaisteacha agus línte táirgthe meaisín píopaí, le taithí fhairsing tionscail agus saineolas teicniúil. Tá Comrise tiomanta do réitigh ardchaighdeáin, ardfheidhmíochta a sholáthar do chustaiméirí domhanda do tháirgeadh píopaí plaisteacha, ag freastal ar raon leathan feidhmeanna.

Leigh Nios moSeol FiosrúchánMeaisín píopa HDPE

Innealra Comrise Is trealamh speisialaithe iad meaisíní píopaí poileitiléin ard-dlúis HDPE a úsáidtear chun píopaí HDPE a mhonarú, a úsáidtear go forleathan i dtionscail éagsúla mar gheall ar a marthanacht, a solúbthacht, agus a bhfriotaíocht in aghaidh creimthe agus ceimiceán. Tá na meaisíní píopa HDPE ardcháilíochta seo deartha chun ábhar HDPE a dhíbirt isteach i bpíopaí trastomhais agus tiús éagsúil, ag freastal ar iarratais ar nós soláthar uisce, dáileadh gáis, córais séarachais, agus píblínte tionsclaíocha.

Leigh Nios moSeol FiosrúchánMeaisín déanta píopaí hdpe

Baintear úsáid den chuid is mó as an meaisín táirgthe píopaí píopaí HDPE agus líne táirgthe píopaí soláthair uisce gáis PP a tháirgtear trí innealra comhghleacaithe chun soláthar agus draenáil uisce talmhaíochta a tháirgeadh, soláthar uisce agus draenáil, leagan cábla, agus gnéithe eile. Is éard atá i meaisín déanta píopaí HDPE ná tábla cáilíochtúil i bhfolús, meaisín tarraingthe, meaisín gearrtha, raca flipping, srl. Tá an meaisín tarraingthe feistithe le dhá chlaw, trí chlaw, ceithre chlaw, sé chlaw, ocht gclao, deich gclao, dhá cheann déag de chlaw agus modhanna tarraingthe eile. Is féidir leat gearrtha saor ó sliseanna a roghnú, gearradh Blade nó gearradh optional, agus tá feidhmíocht iontaofa agus éifeachtúlacht táirgthe ard ag an aonad. Is féidir lenár gcuideachta meaisín déanta píopaí HDPE a tháirgeadh, feadáin bíseach balla istigh, feadáin log balla istigh, agus croí -fheadáin cúr le trealamh tiomnaithe de réir riachtanais úsáideoirí. Tar éis dúinn an t -easbhrúiteoir a athsholáthar, is féidir linn PP, PE, ABS, PPR, PEX, croí -fheadán sileacain agus píopaí ábhair eile a tháirgeadh. Glacann an meaisín gearrtha pláinéadach rialú uimhriúil ríomhaireachta go hiomlán uathoibríoch, a bhfuil na buntáistí a bhaineann le hoibriú éasca agus feidhmíocht iontaofa

Leigh Nios moSeol FiosrúchánLíne táirgthe píopaí HDPE ardchaighdeáin

QINGDAO COMRISE MACHINERY main production line including high-efficiencyHigh quality HDPE pipe production line, PE large-diameter hollow-wall winding pipe production line, PPR cold and hot water supply pipe production line, the inner-rib winding sewage pipe production line, the double-plastic composite winding pipe production line, the continuous winding carat pipe production line, and the PE large-diameter hollow wall production line, the plastic coated corrugated pipe production Líne, líne táirgthe píopa inslithe seaicéad dubh agus líne táirgthe PE/líne an bhoird. Tá níos mó ná 20 cineál táirgí nua ag HC, a dhíoltar go forleathan ar fud an domhain, mar shampla an Rúis, Oirdheisceart na hÁise, an Meánoirthear, agus an Afraic.

Leigh Nios moSeol FiosrúchánCumraíocht ard agus meaisín píopa HDPE 20-110mm ardluais

Is píosa trealaimh speisialaithe é an meaisín píopa PE (poileitiléin) atá deartha chun píopaí poileitiléin a tháirgeadh. Úsáidtear na píopaí seo go forleathan in iarratais éagsúla, lena n -áirítear soláthar uisce, dáileadh gáis, uisciú, agus córais draenála. Cumraíocht Ard agus Meaisín Píobáin HDPE 20-110mm ardluais comhdhéanta de roinnt príomh-chomhpháirteanna a oibríonn le chéile chun táirgeadh píopa éifeachtach agus ardcháilíochta a chinntiú

Leigh Nios moSeol FiosrúchánMeaisín píopa foirceanta bíseach balla log nua

Baineadh úsáid rathúil as meaisín píopaí bíseach balla log nua mar phíopaí draenála chun píopaí stroighne agus píopaí iarainn theilgthe a athsholáthar, agus tá ionchais leathana margaidh acu. Is déantúsóir údarásach é ár gcuideachta de línte táirgthe píopa foirceanta Wall Wall mór-trastomhas sa tSín, le buntáistí teicniúla láidre agus taithí shaibhir maidir le táirgeadh agus suiteáil a chur i bhfeidhm. Tá an dearadh trealaimh chun cinn, tá an chumraíocht ardchríochnaithe, tá an oibríocht iontaofa, tá saol na seirbhíse fada, agus tá aschur na samhla céanna i bhfad níos airde ná leibhéal an tionscail. Go háirithe i gcás samhlacha trastomhais ultra, tá taithí shaibhir againn agus is féidir linn freastal ar riachtanais na gcustaiméirí móra ardleibhéil sa bhaile agus thar lear. Tá táscairí feidhmíochta na líne táirgthe bainte amach ag an leibhéal ceannasach idirnáisiúnta.

Leigh Nios moSeol Fiosrúchán