Meaisín píopa HDPE

QINGDAO COMRISE MACHINERY CO., LTD.

Our main product is HDPE Pipe Machine

The main products are popular in the domestic market, such as the East China market, Southwest market, Northeast market, Central China market, etc. The products are also exported to international markets, including Russia, Australia, Southeast Asia, the Middle East, and Eastern Europe. Africa and other country.

Pe pipe

Good hygiene performance: During the processing of PE pipes, no heavy metal salt stabilizers are added, the material is non-toxic, there is no scaling layer, and there is no bacterial growth, which solves the hidden danger of secondary pollution of urban drinking water.

Excellent corrosion resistance: except for a few strong oxidants, it can withstand corrosion from various chemical media; No electrochemical corrosion.

Long service life: PE pipes can be safely used for more than 50 years at rated temperature and pressure.

Better impact resistance: PE pipes have good toughness, high impact resistance, and can withstand heavy objects directly passing through the pipeline will not cause the pipeline to rupture.

Similer Product

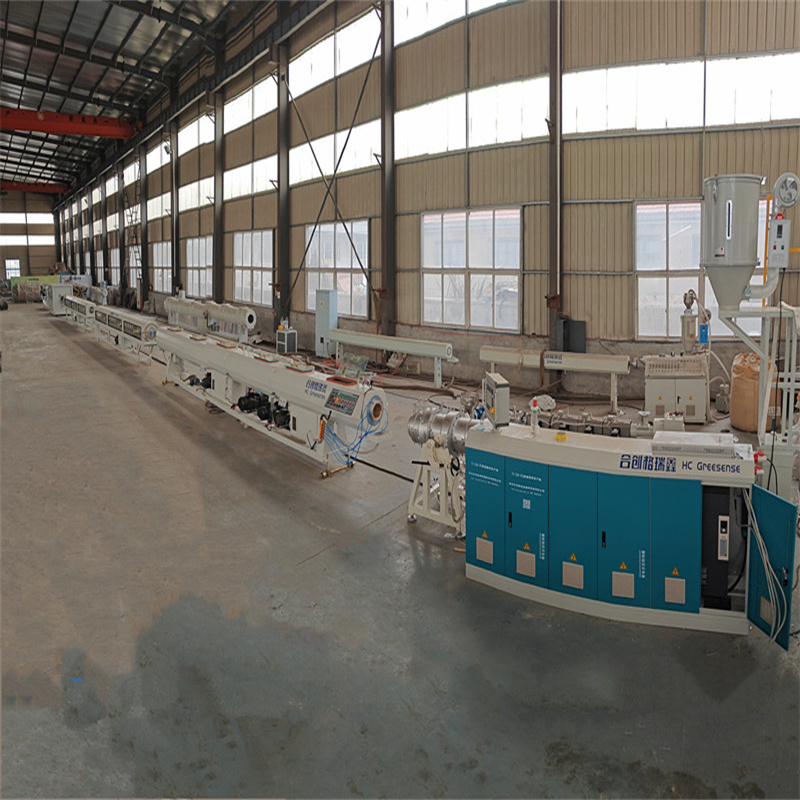

The PE (Polyethylene) pipe machine is a specialized piece of equipment designed for the production of polyethylene pipes. These pipes are widely used in various applications, including water supply, gas distribution, irrigation, and drainage systems. The PE pipe machine consists of several key components that work together to ensure efficient and high-quality pipe production.

ApplicationsWater Supply Systems: Municipal water distribution networks, residential and commercial water supply lines.

Gas Distribution: Natural gas pipelines, propane distribution systems.

Irrigation Systems: Agricultural irrigation, landscaping, and golf course watering systems.

Drainage Systems: Stormwater management, sewage systems, and industrial drainage.

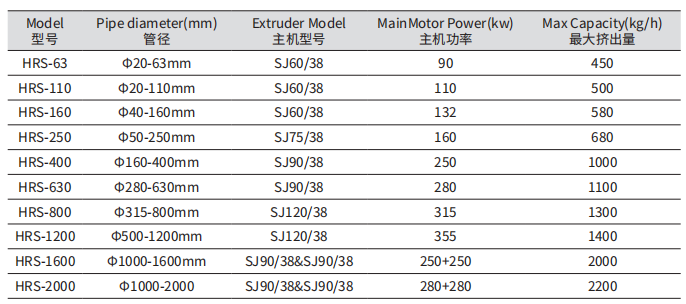

Specifiation Parameters

(1)ExtruderFunction:

The extruder is responsible for melting and extruding the polyethylene pellets into a continuous tube.

Features: High torque drive system, precision temperature control, and efficient screw design for optimal material

processing.

Longth ratio L / D :33:1

Material quality: 38CrMoAlA

Siemens motor

ABB inverter

Siemens PLC computer control panel

(2)New technology die head

The extrusion die adopts spriral structure to ensure uniform melt temperature, completely eliminate weld lines, overcome the stripe defect caused by blue die, and produce pipe products with smooth inner and outer walls and good compactness.

Pressure grades: as to customer table

(3)Vacuum sizing water tankFunction:

The cooling system rapidly cools the extruded pipe to maintain its shape and structural integrity.

Features: Multi-stage cooling tanks with adjustable water flow rates and temperature control to ensure consistent cooling.

vacuum pump:3 + 4 KW, 2 sets

Water pump: 3 + 4 KW, 2 sets

Tank material: 100% Stainless steel

Length: 6000 mm

(4)Spray water tank

Water pump : 4 KW * 1 set

Water tank material:stainless steel

Length : 6000mm

Over all size :6500×500×1300mm

(5)Halling off machine:

The traction device is designed to be able to pull the pipe in a continuous and stable state. Its compact structure, maintenance-free structure and absolute balance of operation are its outstanding features.

Clamping way:claw pneumatic

Traction speed:1-15m/min

Pulling motor:motor 1.5KW x 2

Mode of speed regulation:Frequency Control

(6)Cutting machine:

Cutting method:Rotary cutting with circular blade

Clamping way:Pneumatic clamp

Worktable movement way: Synchronous follow up, pneumatic reset

Revolution motor power:1.5KW

Method of electric control : Independent setting of high-speed counter and PLC linkage

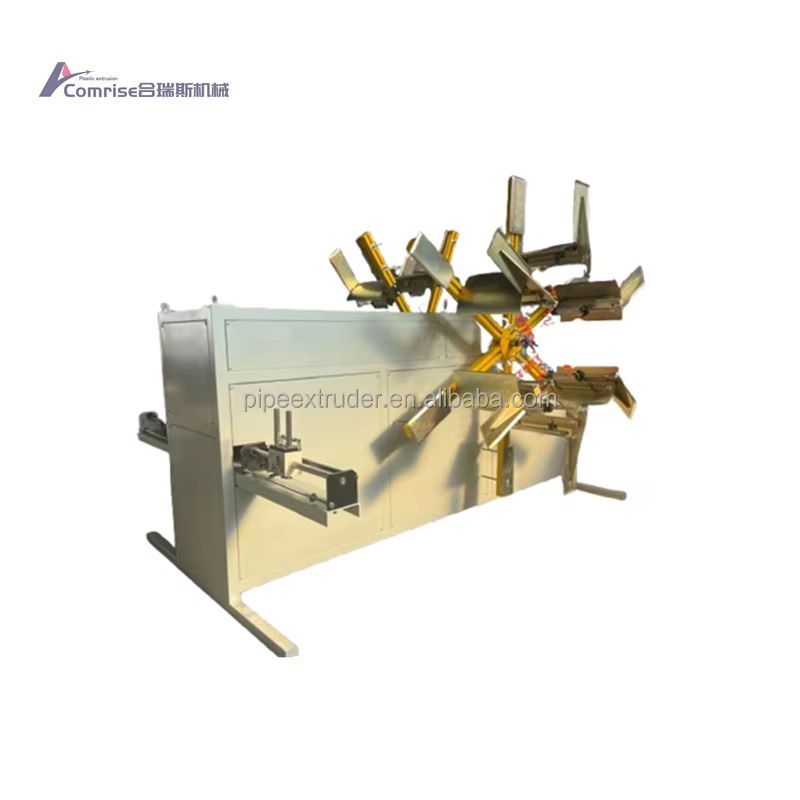

(7)Double station winding machine

The winding machine is used for small-sized 20-63mm PP PE PPR HDPE LDPE pipes. High winding efficiency

(8)Auto stocker

Stacker used for big size pipe.

About Us

High Production Efficiency:

Advanced extrusion technology ensures high output and consistent quality.

Automated control systems for precise operation and reduced labor costs.

Versatile Material Handling:

Capable of processing a wide range of polyethylene grades, including HDPE, MDPE, and LDPE.

Flexible production settings to accommodate different pipe diameters and wall thicknesses.

User-Friendly Interface:

Intuitive control panel with touch screen display for easy operation and monitoring.

Real-time data tracking and production statistics for better process control.

Robust Construction:

Heavy-duty frame and components for durability and long service life.

Low maintenance requirements and easy access for routine servicing.

Environmental Compliance:

Energy-efficient design to reduce power consumption and operating costs.

Minimal waste generation and recycling options for sustainable production.

GET A QUOTATION NOW

- View as

Líne easbhrúite píopa ppr

Is córas táirgthe speisialaithe é líne easbhrúite PPR PPR atá deartha chun píopaí copolymer randamach polapróipiléine (PPR) a mhonarú, a úsáidtear go forleathan i gcórais iompair pluiméireachta, téamh agus sreabhach tionsclaíoch. Tá an líne easbhrúite in ann píopaí a tháirgeadh i trastomhais éagsúla (m.sh., 16-63mm nó 20-110mm) agus struchtúir (ciseal aonair nó ilchiseal), ag brath ar na riachtanais iarratais.

Leigh Nios moSeol FiosrúchánMeaisín píopa ppr

Úsáidtear meaisíní píopa PPR chun píopaí copolymer randamacha polapróipiléine (PPR) a tháirgeadh, a úsáidtear go forleathan i gcórais uisce fuar agus te, córais téimh, agus feidhmchláir eile. Ag brath ar riachtanais táirgthe, is féidir leis na meaisíní seo píopaí a tháirgeadh i méideanna éagsúla, idir trastomhas 16-63mm nó 20-110mm. Ina theannta sin, is féidir le píopaí PPR a bheith ina struchtúir aonchiseal nó trí chiseal, ag brath ar an iarratas.

Leigh Nios moSeol FiosrúchánMeaisín easbhrúite HDPE

Cén fáth a roghnaíonn Comrise HDPE Machine?

Cuireann ár gcuideachta meaisíní easbhrúite HDPE ar fáil le teicneolaíocht agus iontaofacht nua. Soláthraímid réitigh saincheaptha chun freastal ar riachtanais táirgthe ar leith, ag cinntiú na feidhmíochta is fearr agus an cost-éifeachtúlacht. Le fócas ar inbhuanaitheacht agus ar nuálaíocht, tá ár meaisíní easbhrúite HDPE deartha chun cabhrú leat fanacht iomaíoch sa mhargadh HDPE atá ag dul i méid. Iontaobhas dúinn na huirlisí a theastaíonn uait a sheachadadh le haghaidh déantúsaíocht táirgí HDPE ardcháilíochta.

Meaisín easbhrúite píopaí

Is bunchloch é an meaisín easbhrúite píopa comraid Machienry, a chuireann ar a gcumas déantúsaíocht éifeachtach agus beacht píopaí ó ábhair theirmeaplaisteacha éagsúla, lena n-áirítear HDPE (poileitiléin ard-dlúis), PVC (clóiríd pholaivinile), agus PP (polypropylene). Tá ról ríthábhachtach ag an ard-innealra seo i dtionscail a bhíonn ag brath ar phíopaí ardchaighdeáin le haghaidh bonneagair, fóntais agus feidhmchláir thionsclaíocha. Leis an gcumas atá aige píopaí de thrastomhais, de thiús, agus de fhaid éagsúla a tháirgeadh, tá an meaisín easbhrúite píopaí ina uirlis fíor -riachtanach do mhonaróirí ar fud an domhain.

Leigh Nios moSeol FiosrúchánMeaisín Déantúsaíochta Píobáin HDPE

Déanann Innealra Comrise Qingdao speisialtóireacht i ndearadh, i bhforbairt agus i ndéantúsaíocht línte táirgthe píopaí HDPE (poileitiléin ard-dlúis) agus meaisín déantúsaíochta píopaí HDPE. Le blianta de thaithí sa tionscal innealra plaisteach, tá muid féin mar ainm iontaofa maidir le réitigh nuálacha agus éifeachtúla a sholáthar do mheaisín déantúsaíochta píopaí HDPE. Tá ár bhfoireann innealtóirí agus teicneoirí oilte tiomanta d'innealra a sheachadadh a chomhlíonann na caighdeáin idirnáisiúnta is airde. Táimid bródúil as ár gcumas réitigh shaincheaptha a thairiscint atá saincheaptha do riachtanais shonracha ár gcliant, ag cinntiú na feidhmíochta agus an iontaofachta is fearr.

Leigh Nios moSeol FiosrúchánMeaisín píopa plaisteach

Innealra Comrise Monaróir ceannródaíoch Síneach a dhearann i ndearadh agus i dtáirgeadh meaisín easbhrúite píopa plaisteach agus línte táirgthe iomlána. Le blianta fada de shaineolas, déanaimid cumhacht a thabhairt do thionscail ar fud an domhain trí réitigh a sheachadadh go hiomlán le haghaidh meaisín píopaí plaisteacha, rud a chumasaíonn táirgeadh píopaí durable, ardfheidhmíochta d'iarratais éagsúla.

Leigh Nios moSeol Fiosrúchán